This machine is suitable for loosening and tightening bolts and nuts of railway sleepers. The machine has large impact force and centralized operation, which can meet the locking torque of rail fasteners and is convenient and fast. A walking device is installed on the base, which can walk on land or on rails. It is easy to carry and is an ideal special tool for loosening and tightening sleeper nuts instead of heavy manual labor.

Usage and maintenance

1. Check whether the transmission part is flexible and whether the threaded connection is loose.

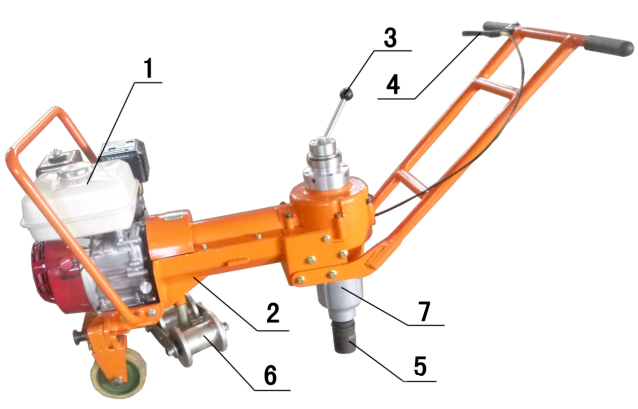

2. Turn the reversing handle 3 so that the working part of the socket wrench is in the neutral position (empty position).

3. Add engine oil and fuel according to the engine operating instructions, start the engine and run it without load for a short time. After it runs normally, it is ready to start working.

4. Place the equipment on the rail, pull out the latch at the rotating shaft of the land running wheel, turn the land running wheel to both sides, and then insert the latch into the positioning hole to prevent the land running wheel from scratching the rail when the equipment is working, causing trouble during operation. Inconvenient.

5. Turn the reversing handle 3 to the required direction of rotation (tight, loose), hold the operating handle, align and tighten the nut, and use your right hand to rotate the throttle handle 4. Do not pull the throttle lever too hard to avoid damaging the throttle. , that is, impact tightening and loosening of the nut.

6. When tightening, you can loosen the throttle handle 4 when you hear a clicking sound, and lift the sleeve 5. If the torque is not enough, you can hit it a few more times.

7. Before stopping work, first adjust the gasoline engine to idle speed for 3 to 5 seconds, then move the gear to the neutral position, and then turn off the engine. Then pull out the latch at the land running wheel, put the running wheel down, insert the latch into the positioning hole, and then lift the device down.

8. When changing direction, be sure to loosen the accelerator handle first to make the gasoline engine idle, and then loosen or tighten the direction change.

9. The eccentric sleeves of the transmission shaft, universal coupling, gear mechanism, and reversing handle 3 should be inspected and filled with molybdenum disulfide grease once a week. Keep them clean and inspected once a month. After cleaning with kerosene, add 2 Molybdenum sulfide grease.

10. Afterburner 7 is inspected once a month. After cleaning it with kerosene, add gear oil to keep it clean.

11. The rolling bearings of the running wheels should be inspected once every two months of operation. After cleaning with diesel, add molybdenum disulfide grease to keep them clean and ensure smooth operation.

Contact: Coco

Phone: +86-15563707858

Tel: +86-15563707858

Email: sdsinostar@hotmail.com

Add: Jining Economic energy conservation and environmental protection Industrial Park

We chat